TP-K16 CCTV camera︎

TK-K16 CCTV camera, inventory No. MIM 700/VI/83; created: 1980s, 20 th century; manufacturer: Unitra Polkolor Kinescope Plant; location: Warsaw, Poland; materials: aluminium, rubbers, copper, steel, glass, plastics; dimensions [mm]: H. 134, W 100, D 320.

The Unitra Polkolor Kinescope Plant, established in 1976, was one of the main targets of strategic investments made during the leadership of Edward Gierek. These investments sought the development of plants for the high-tech industry, and more specifically, for Polish electronics. The plant in question primarily manufactured colour kinescopes from components brought in from elsewhere. It operated as a domestic enterprise until 1991, when under ownership changes, it was rebranded to Thomson Polkolor (#workplace). This was a “joint venture” company, with French Thomson Consumer Electronics holding the majority of shares. The company changed its name several times in following years. In 2005, the plant in Piaseczno was sold to an Indian investor, Videocon Industries Limited (#global_production_network), and four years later the decision was made to discontinue production at the plant.

Nonetheless, Unitra products continue to circulate within networks of distribution, given that they generate social relations. The year of 2006 saw the establishment of the UNITRA-Club, “a non-profit venture aimed at popularizing and maintaining the memory of Polish electronic devices manufactured in companies forming the former »Zjednoczenie Przemysłu Elektronicznego UNITRA« (UNITRA Union of the Electronic Industry)”. This virtual “commemoration” space is professionally managed, is replete with resources regarding specific items (service manuals, operation manuals, spreadsheets), maintains their circulation (the Giełda – Sprzedam/Kupię (Market – Sell/Buy) tab), and also groups together enthusiasts (the forum is divided into sections): Dla początkujących, Serwis, Ogólnie, Kąciki zainteresowań, Nasz sprzęt, Zaginione, Klubokawiarnia - (For beginners, Service, General, Interest corners, Our equipment, Lost, Club-café). At the time of writing this text, the website has recorded 20,001 club subscribers, who have opened 5,505 discussion threads and published 88,514 posts, conducting the voluntary and community work of developing knowledge on Unitra (#social_capital #sense_of_community #grassroot_heritagisation).

Among the many uses of the CCTV camera, a particularly interesting use is that which is aimed at monitoring the workplace (#work_control #work_control_tools #monitoring #disciplining_tools). The camera acts as a sort of starting point for discussions on the transformation of employee monitoring procedures. Supervision of workers in the PRL consisted predominantly of supervision of their interpersonal relations and was undertaken by industrial guards. Around a dozen guards met several million industrial plant workers every day. The figure of the industrial guard was a permanent element of work inspection. The appearance of a device capable of recording the workplace significantly impacted the experience of controlling and controlled persons.

The position of the industrial guard in the industrial plants of post-war Poland was already regulated by 1949, when the Internal Security Corps Industrial Protection Inspectorate (IOP) was established. Four years later, the IOP would organize the work of approximately 30 thousand industrial guards, who protected 1,200 plants. Their tasks included preventing crimes, such as theft or wastage, and protecting against the espionage and diversion threats created by state hysteria. In 1956, the IOP was renamed the Chief Industrial Inspectorate and incorporated into the structures of the Ministry of Interior. The act on Industrial Guards, which unified the protection of workplaces, was announced in January 1961. Under the act, the tasks of the Industrial Guard included:

The members of this armed formation had the right to:

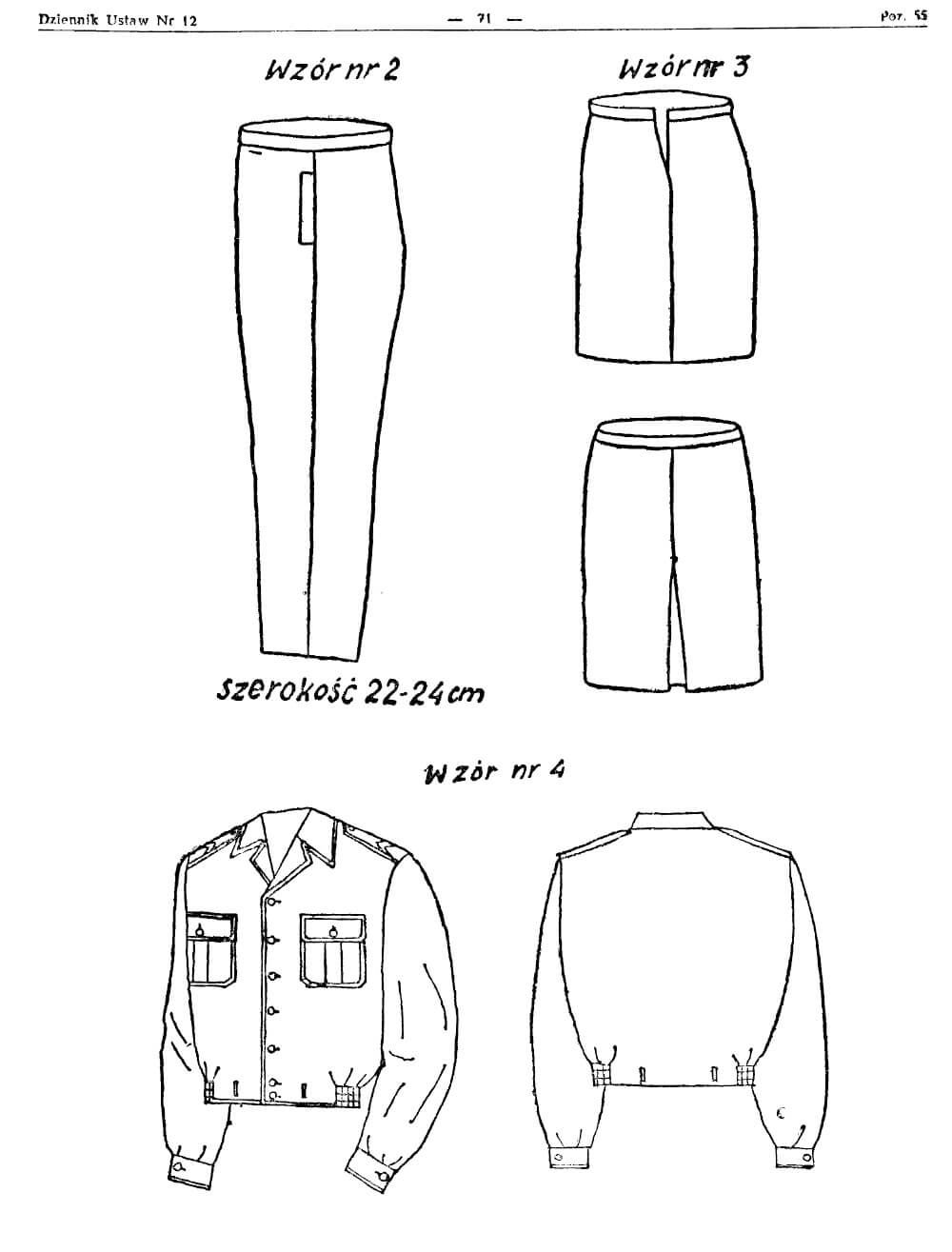

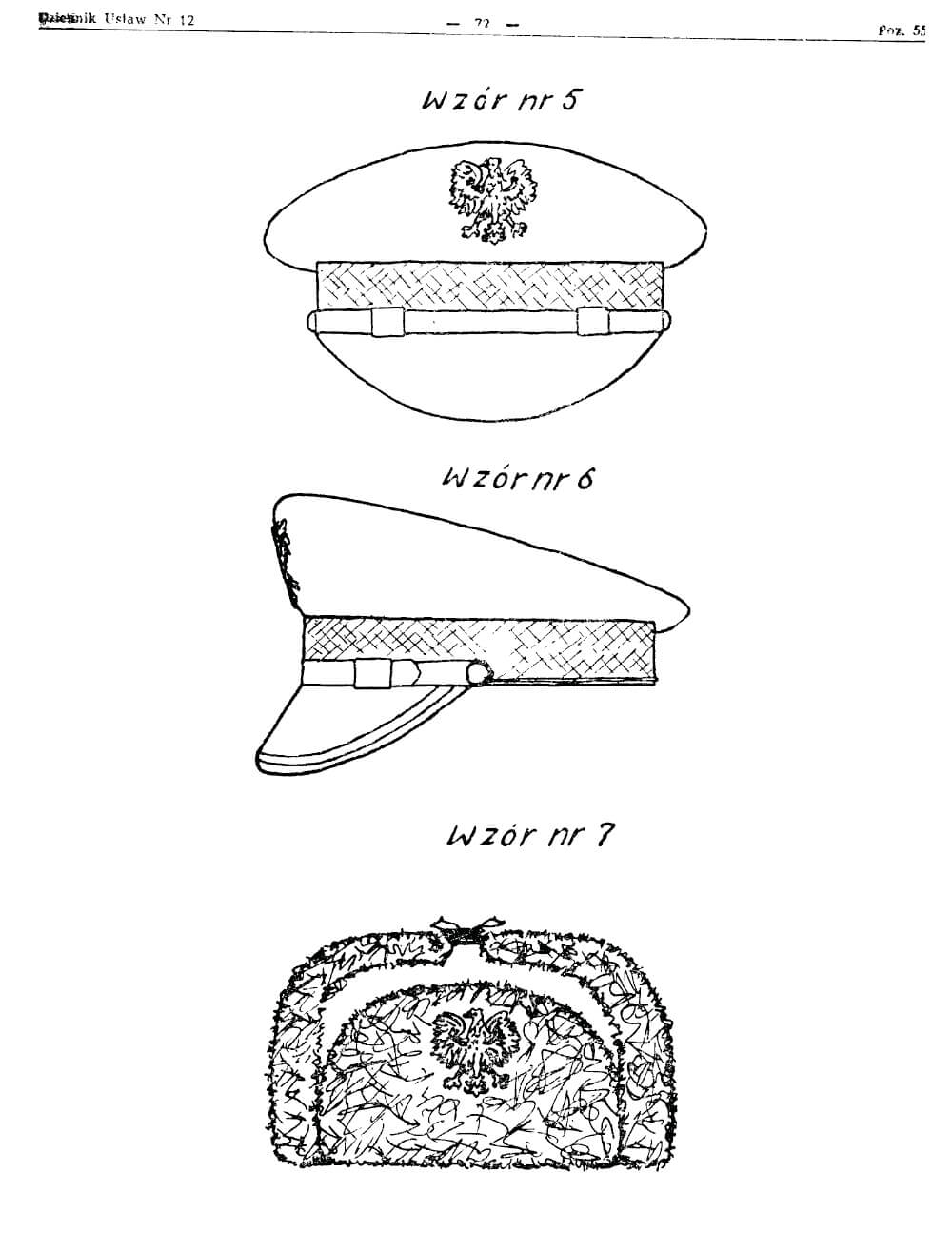

The Industrial Guard was armed and uniformed. The uniform of the guard consisted of: a navy-blue garrison cap with a green rim; a winter hat, usually an industrial ushanka; a navy-blue forage-cap; a jacket; trousers, or a skirt for women (#work_clothing #employee_segregation_due_to_gender); a navy-blue coat; a steel-coloured shirt; a windbreaker; a navy blue tie and scarf; black footwear; felt sentry boots; and cotton gloves. In addition, a membership badge, displaying crossed rifles inscribed in a toothed wheel, was mandatory (#work_emblem).

Work as an Industrial Guard was not well paid. In 1956, the average salary was 546 zlotys (whilst the national standard was 1100 zlotys), and in 1968, it ranged from 700 to 1170 zlotys. For comparison, the average salary of a worker at the “Cegielski” Works in Poznań, protected by the Industrial Guard, was 2715 zlotys. This work often constituted an additional source of income (#low_paid_job). As indicated in the report „Realizacja podstawowych zadań Głównego i Wojewódzkich Inspektoratów Ochrony Przemysłu za lata 1968–1969” (The implementation of basic tasks assigned to the Chief and Provincial Industrial Protection Inspectorates for the years 1968-1969”) from 1970:

The Industrial Guard functioned until the transformation of the prevailing system. The liquidation of the Ministry of Interior Chief Industrial Protection Inspectorate commenced by way of a regulation of the minister in 1989, and Industrial Guard activity was suspended by the Act of 22 August 1997 on the protection of persons and property. The role of guards was taken over primarily by the employees of private security companies, as well as by monitoring equipment (#work_automation). The operation of the latter required new technical skills and generated new practices and manners of engaging the working body. There was, for example, an intensification of visual work, as it became necessary to track transmissions recorded by the cameras and to look for changes in fixed workplace images (#involving_senses).

Employee supervision methods were also transformed. In their book Cięcia. Mówiona historia transformacji, Aleksandra Leyk and Joanna Wawrzyniak write:

Of course, the expansion of the surveillance experience is not a distinguishing factor of just the post-transformation period. Already in the PRL period, inspections were expected in places beyond the confines of the workspace, for example at the entrance gate. Vigilance was evoked by the presence of colleague-denouncers or the influence of political decision-makers. However, the introduction of a device recording work images, a machine that is hard to negotiate with (followed by subsequent disciplining tools, such as e-mail monitoring), depersonalized control and gave rise to a number of questions on the limits of privacy and work engagement.

︎

Nonetheless, Unitra products continue to circulate within networks of distribution, given that they generate social relations. The year of 2006 saw the establishment of the UNITRA-Club, “a non-profit venture aimed at popularizing and maintaining the memory of Polish electronic devices manufactured in companies forming the former »Zjednoczenie Przemysłu Elektronicznego UNITRA« (UNITRA Union of the Electronic Industry)”. This virtual “commemoration” space is professionally managed, is replete with resources regarding specific items (service manuals, operation manuals, spreadsheets), maintains their circulation (the Giełda – Sprzedam/Kupię (Market – Sell/Buy) tab), and also groups together enthusiasts (the forum is divided into sections): Dla początkujących, Serwis, Ogólnie, Kąciki zainteresowań, Nasz sprzęt, Zaginione, Klubokawiarnia - (For beginners, Service, General, Interest corners, Our equipment, Lost, Club-café). At the time of writing this text, the website has recorded 20,001 club subscribers, who have opened 5,505 discussion threads and published 88,514 posts, conducting the voluntary and community work of developing knowledge on Unitra (#social_capital #sense_of_community #grassroot_heritagisation).

Among the many uses of the CCTV camera, a particularly interesting use is that which is aimed at monitoring the workplace (#work_control #work_control_tools #monitoring #disciplining_tools). The camera acts as a sort of starting point for discussions on the transformation of employee monitoring procedures. Supervision of workers in the PRL consisted predominantly of supervision of their interpersonal relations and was undertaken by industrial guards. Around a dozen guards met several million industrial plant workers every day. The figure of the industrial guard was a permanent element of work inspection. The appearance of a device capable of recording the workplace significantly impacted the experience of controlling and controlled persons.

The position of the industrial guard in the industrial plants of post-war Poland was already regulated by 1949, when the Internal Security Corps Industrial Protection Inspectorate (IOP) was established. Four years later, the IOP would organize the work of approximately 30 thousand industrial guards, who protected 1,200 plants. Their tasks included preventing crimes, such as theft or wastage, and protecting against the espionage and diversion threats created by state hysteria. In 1956, the IOP was renamed the Chief Industrial Inspectorate and incorporated into the structures of the Ministry of Interior. The act on Industrial Guards, which unified the protection of workplaces, was announced in January 1961. Under the act, the tasks of the Industrial Guard included:

1) ensuring workplace safety,

2) guarding property within workplace premises and, if required, escorting entrusted property,

3) controlling rights to enter the premises and taking out or removing property.

The members of this armed formation had the right to:

1) check the papers of people entering and exiting a workplace,

2) if required by the protection of workplace property – searching people and means of transport at the order of the plant manager and within plant premises. The objective was to verify whether workplace property is not unlawfully removed or exported (…),

3) detaining people caught red-handed or suspected of committing a crime within workplace premises, in the event of a fear of escape, covering the tracks or if their identity is unknown (…),

4) using weapons in the following cases:

a) self-defence and defence of others protecting the plant and its property, to repel a direct and violent attack threatening the life or aimed at disarmament,

b) in the event of a failure to heed the call to immediately put down a weapon or any other dangerous tool (…),

c) to repel an attack on a protected facility and property of significant value or escorted property,

d) to prevent the escape of the perpetrator of the attack referred to in a), b) and c).

The Industrial Guard was armed and uniformed. The uniform of the guard consisted of: a navy-blue garrison cap with a green rim; a winter hat, usually an industrial ushanka; a navy-blue forage-cap; a jacket; trousers, or a skirt for women (#work_clothing #employee_segregation_due_to_gender); a navy-blue coat; a steel-coloured shirt; a windbreaker; a navy blue tie and scarf; black footwear; felt sentry boots; and cotton gloves. In addition, a membership badge, displaying crossed rifles inscribed in a toothed wheel, was mandatory (#work_emblem).

Work as an Industrial Guard was not well paid. In 1956, the average salary was 546 zlotys (whilst the national standard was 1100 zlotys), and in 1968, it ranged from 700 to 1170 zlotys. For comparison, the average salary of a worker at the “Cegielski” Works in Poznań, protected by the Industrial Guard, was 2715 zlotys. This work often constituted an additional source of income (#low_paid_job). As indicated in the report „Realizacja podstawowych zadań Głównego i Wojewódzkich Inspektoratów Ochrony Przemysłu za lata 1968–1969” (The implementation of basic tasks assigned to the Chief and Provincial Industrial Protection Inspectorates for the years 1968-1969”) from 1970:

Most Industrial Guard workers come from the countryside, with 46% having their own farm. A significant group is unable to implement the most complex security tasks due to distant commuting and being overburdened with farm work.

Furthermore, the guards were accused of poor effectiveness, with their performance assessed on the basis of analyses of plant losses and detected illegal activity. There were also accusations of complicity in such activities: in 1968, 2,212 workers resigned from work at Industrial Guard, with 13% dismissed due to disciplinary action.

The Industrial Guard functioned until the transformation of the prevailing system. The liquidation of the Ministry of Interior Chief Industrial Protection Inspectorate commenced by way of a regulation of the minister in 1989, and Industrial Guard activity was suspended by the Act of 22 August 1997 on the protection of persons and property. The role of guards was taken over primarily by the employees of private security companies, as well as by monitoring equipment (#work_automation). The operation of the latter required new technical skills and generated new practices and manners of engaging the working body. There was, for example, an intensification of visual work, as it became necessary to track transmissions recorded by the cameras and to look for changes in fixed workplace images (#involving_senses).

Employee supervision methods were also transformed. In their book Cięcia. Mówiona historia transformacji, Aleksandra Leyk and Joanna Wawrzyniak write:

The workers were subjected to new disciplining techniques, which hindered the maintenance of social relationships. Worker monitoring became much more direct. It involved prohibiting discussion during production, making free movement around the factory more difficult or increasing the working hour and workflow control. “We had these controllers. If at least he managed activities. I could cope with that. But he just stood at the stair landing and watched. Like in a jail” (Jagoda, anonymized facility).

Of course, the expansion of the surveillance experience is not a distinguishing factor of just the post-transformation period. Already in the PRL period, inspections were expected in places beyond the confines of the workspace, for example at the entrance gate. Vigilance was evoked by the presence of colleague-denouncers or the influence of political decision-makers. However, the introduction of a device recording work images, a machine that is hard to negotiate with (followed by subsequent disciplining tools, such as e-mail monitoring), depersonalized control and gave rise to a number of questions on the limits of privacy and work engagement.

︎