mangle︎

Mangle, inventory No. MIM 2878/IX/341/; created: 1920s; manufacturer: (probably) J. Schammel Spezialfabrik für Wäschemangeln; location: Wrocław; materials: metals, brass, wood; dimensions [mm]: H 1500, W 1250, L 2700.

A mangle, or linen press, is a device used to mangle, or iron, items using a roller system. Larger linen items are usually mangled after laundering. Ironing these items with a domestic iron would be ineffective, time-consuming, and cumbersome. The mangle has taken various forms, from that of a household appliance to that of an industrial machine. The function of the mangle has evolved over the centuries: the mangle began as a wringer used to squeeze water out of wet laundry; now the mangle appears as a modern electric device used to iron or flatten utility fabrics (#reproductive_work).

The MIM collection includes a manual commercial mangle (chest mangle), most probably manufactured by J. Schammel Spezialfabrik für Wäschemangeln in Wrocław. The exact manufacturing date is unknown, but the mangle is likely to have originated in the early 20th century.

The machine consists of a massive wooden frame, base, rollers, and a chest. Steel elements, such as a chest-driving system, are fixed to the frame. The stone-filled chest would have been used as the mangling element (cold mangle). Materials were carefully wound around the rollers under the chest, avoiding folds or creases, and turning the crank moved the rollers over the linen (#work_tools).

The mangle was a large and costly device, used by large households and laundries. Special commercial points that offered linen mangling were established. Operating a mangle required a lot of work. The machine was heavy and took up plenty of space (#manual_work #effort #labour_intensity).

Service points that now offer linen mangling are usually fitted with electrically driven large mangles with heated cylinders which ensure the rapid and effective mangling of even the largest linen items at an elevated temperature. Since these heated cylinders use gas, these mangles are referred to as electric and gas mangles. Bedding for mangling is inserted between the rollers, which are additionally heated using gas or electricity. Pressure is applied by springs and adjusted using knobs (#work_mechanisation).

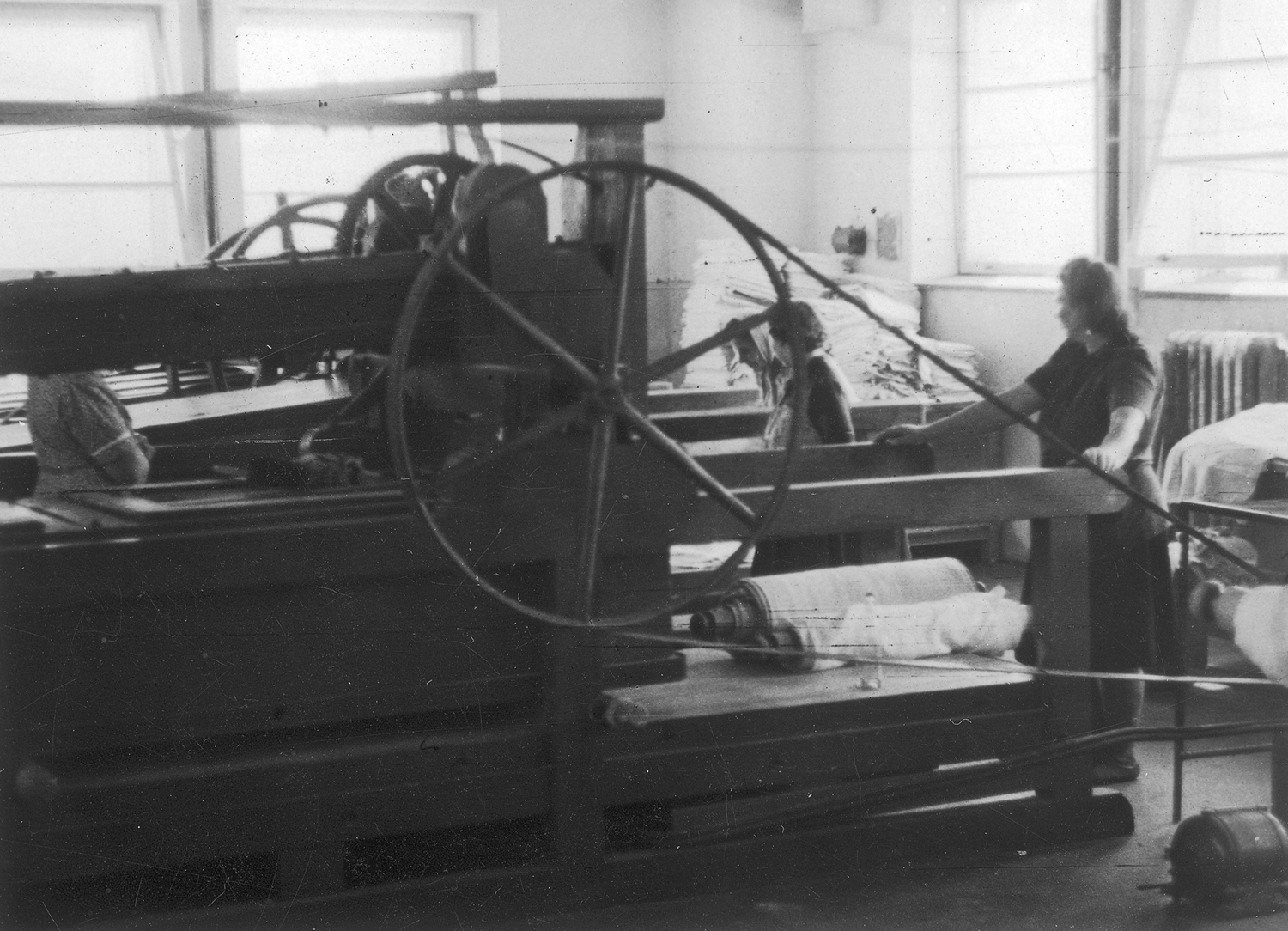

Work at a mangle shop service_work in the 1970s and 1980s

For 10 years in the 1970s and 1980s, Maria Kasperek worked in a laundry with a mangle, in Tychy. This service outlet belonged to the Housing Cooperative in Tychy. According to an interview, the outlet primarily served workers’ hostels, but also served individual customers who were residents of nearby blocks of flats and hamlets (villages near the city boundaries). There were several laundries within city limits, but not all had mangles.

Work at the mangle on Tołstoja Street followed a two-shift system, with one shift lasting from 6 a.m. to 1 p.m. and another from 1 p.m. to 8 p.m. Both shifts were observed on weekdays, but only the first shift was observed on Saturdays. The crew consisted of 6 people who were all women (#employee_segregation_due_to_gender).

The laundry house was equipped with two large boilers and a gas burner where starch was cooked to be later added to the laundry during the last rinsing cycle. The mangle was a large electrically powered device. Mangling took place after drying laundered items. A mangle shaft was wrapped with white felt which was replaced approximately every two weeks by maintenance workers, who also verified machine efficiency at the end of each working day. If the felt was yellowish due to wear, white fabrics would also be yellowed. The devices in the outlet worked for a dozen or so hours a day, generating heat, therefore the place was characterized by high temperature and a specific odour of starch in the air (#high_temperature). The mangle could be operated by a single person.

When asked if working at a mangle shop was demanding, the interviewee responded that it was not a hard job, though sometimes required carrying heavy bundles of laundry. The interlocutor has fond memories of working at this place, talking about her friends with great sentiment. This job was not associated with any risk of accidents. Mangle workers had to wear protective footwear, aprons, and gloves. The outlet continued operating during Martial Law. At the end of the 1990s, the outlet was privatized (#state_sector #private_sector #protective_clothing).

A mangle shop, besides providing laundry and ironing services, was a place to meet, exchange information, and gossip within a community (#sense_of_community #team_work).

︎

The MIM collection includes a manual commercial mangle (chest mangle), most probably manufactured by J. Schammel Spezialfabrik für Wäschemangeln in Wrocław. The exact manufacturing date is unknown, but the mangle is likely to have originated in the early 20th century.

The machine consists of a massive wooden frame, base, rollers, and a chest. Steel elements, such as a chest-driving system, are fixed to the frame. The stone-filled chest would have been used as the mangling element (cold mangle). Materials were carefully wound around the rollers under the chest, avoiding folds or creases, and turning the crank moved the rollers over the linen (#work_tools).

The mangle was a large and costly device, used by large households and laundries. Special commercial points that offered linen mangling were established. Operating a mangle required a lot of work. The machine was heavy and took up plenty of space (#manual_work #effort #labour_intensity).

Service points that now offer linen mangling are usually fitted with electrically driven large mangles with heated cylinders which ensure the rapid and effective mangling of even the largest linen items at an elevated temperature. Since these heated cylinders use gas, these mangles are referred to as electric and gas mangles. Bedding for mangling is inserted between the rollers, which are additionally heated using gas or electricity. Pressure is applied by springs and adjusted using knobs (#work_mechanisation).

Work at a mangle shop service_work in the 1970s and 1980s

For 10 years in the 1970s and 1980s, Maria Kasperek worked in a laundry with a mangle, in Tychy. This service outlet belonged to the Housing Cooperative in Tychy. According to an interview, the outlet primarily served workers’ hostels, but also served individual customers who were residents of nearby blocks of flats and hamlets (villages near the city boundaries). There were several laundries within city limits, but not all had mangles.

Work at the mangle on Tołstoja Street followed a two-shift system, with one shift lasting from 6 a.m. to 1 p.m. and another from 1 p.m. to 8 p.m. Both shifts were observed on weekdays, but only the first shift was observed on Saturdays. The crew consisted of 6 people who were all women (#employee_segregation_due_to_gender).

The laundry house was equipped with two large boilers and a gas burner where starch was cooked to be later added to the laundry during the last rinsing cycle. The mangle was a large electrically powered device. Mangling took place after drying laundered items. A mangle shaft was wrapped with white felt which was replaced approximately every two weeks by maintenance workers, who also verified machine efficiency at the end of each working day. If the felt was yellowish due to wear, white fabrics would also be yellowed. The devices in the outlet worked for a dozen or so hours a day, generating heat, therefore the place was characterized by high temperature and a specific odour of starch in the air (#high_temperature). The mangle could be operated by a single person.

When asked if working at a mangle shop was demanding, the interviewee responded that it was not a hard job, though sometimes required carrying heavy bundles of laundry. The interlocutor has fond memories of working at this place, talking about her friends with great sentiment. This job was not associated with any risk of accidents. Mangle workers had to wear protective footwear, aprons, and gloves. The outlet continued operating during Martial Law. At the end of the 1990s, the outlet was privatized (#state_sector #private_sector #protective_clothing).

A mangle shop, besides providing laundry and ironing services, was a place to meet, exchange information, and gossip within a community (#sense_of_community #team_work).

︎